Information System at Tata Motors

About Tata Motors –

Tata Motors Limited,India’s largest automobile company, with consolidated revenues of Rs.1,23,000 crores (USD 27 billion) in 2010-11 is located in Mumbai, India. The Company’s manufacturing facilities are located in Jamshedpur (Jharkhand), Pune (Maharashtra), Lucknow (Uttar Pradesh), Pantnagar (Uttarakhand), Sanand (Gujarat) and Dharwad (Karnataka). Tata Motors is also expanding its international footprint in several countries inEurope,Africa, theMiddle East,South East Asia,South AsiaandSouth America. The offices and manufacturing units are design to produce mid size cars, trucks, buses and other commercial vehicles. Close to 4 million Tata vehicles ply on Indian roads, since the first rolled out in 1954. Today TATA motors’ vehicles run in more than 70 countries with strength of 24,000 employees all over the globe.

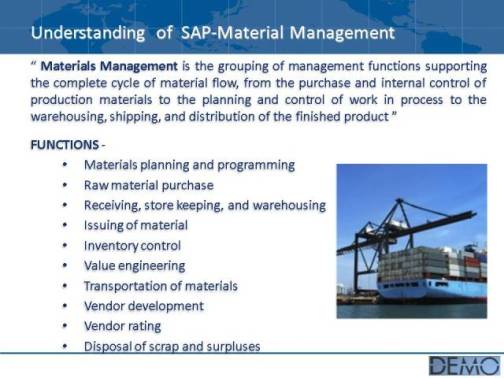

Producing thousands vehicles per week, operating on a back to back production cycle, Information system were a key to the operation of the facility, and hence, they had to get going, and on-line, fast. Tata Motors builds vehicles in a production environment. To meet the high expectations of customers in this market segment, the company requires flexibility and speed, business integration and automation of the process.

The Challenges –

Information system is vital in maintaining the production rate in a cost-effective, customised environment. Tata plants acrossIndiaare supported by mainframe-based information systems which then connected to the different system and applications. The result are high maintenance cost and complicated system integration. The amount of time and money that the company spend on system maintenance is very high, and the goal was to keep the IT costs as low as possible.

The company desperately wanted an integrated information system, so that the flow of information becomes fast and effective. They wanted to enter data only once as every dealer and other key employee were managing information separately with legacy-based systems, the environment produced inconsistent data, making interpretations difficult and resulting in inefficient planning for capacity and spare parts. The company wanted a centralised system where the entered information automatically sent to all the functional areas like – financial systems, material management, ordering etc without delay, caused by data interface or any other data transferring problems.

The Solution –

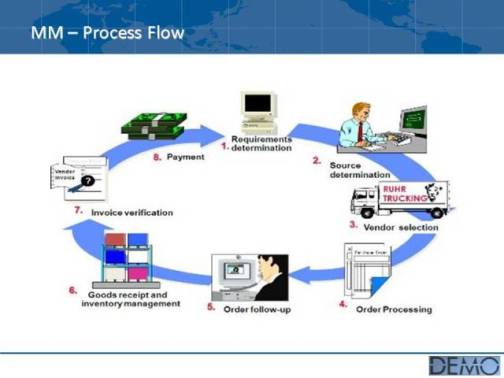

At first Tata Motors created an operational model which shows the process flow, they then used this model to find the best suit application tool available in the market to meet their business need. In addition to being able to match the processes, Tata’s criteria for the software includes global scope, latest tools and technology, end to end full integration without any interface problems and configurable documents.

Tata put together a list of the top five vendors in the marketplace and mapped the system against its need. SAP R/3 was the best fit of all. According to the most of company’s opinion; SAP provided the best standard software solution in the industry for their requirements.

Tata then decided to go with SAP implementation. They outsourced this task to Tata Technologies as their implementation partner. SAPIndiaprovided all the support and consultation for the implementation. While the implementation process was on, in 1997 they have realised that WAN infrastructure inIndiado not support single server implementation. Hence a distributed server implementation has to be done and it took almost 2 years between 1998 and 2000. Later in 2003 they upgraded from distributed server to single server platform. At present there are around 4000 users across the country using SAP version 6.0 since 2008.

The Benefits –

Once SAP was implemented, automation of several processes helped in reducing the cost and time. Almost all the business process like material, order, logistics etc were all now sharing the centralised information system which is not totally location independent. Tata Motors later adopted some more modules and tools of SAP for better business process and functionality.

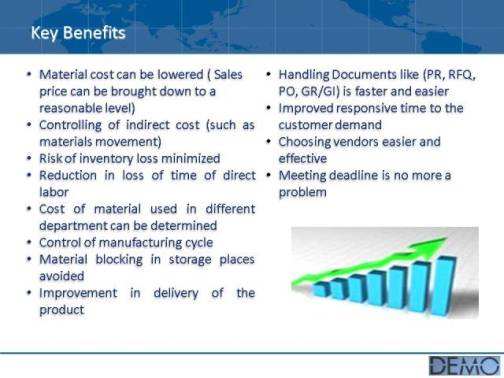

Tata experienced benefits in productivity and cost control. The number of servers and applications run on them has been reduced drastically. Some other benefits they experienced are as below –

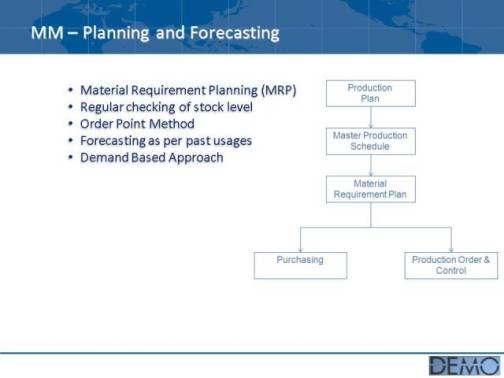

Manufacturing: Production planning and material management became automatic

Documents: Invoicing, orders and other documents are now generated automatically

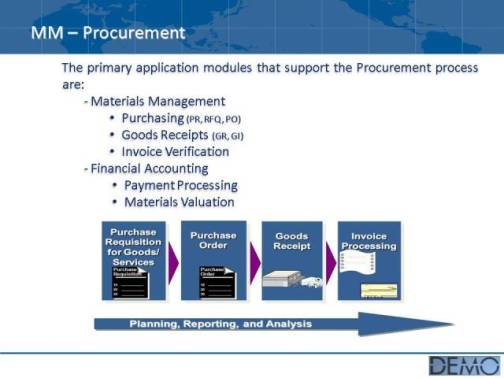

Requisitioning: Purchasing and finding the best vendor or supplier became easier.

Reporting and Analysis: Standard and specific reports can now be generated just by a click, analysing and comparing the reports is now automatic

Decision-making: Availability of online information, analysis and better planning toots helped Tata managers to take better decisions.

Questions with answer –

Que 1. Point out the five basic problems Tata was facing?

Ans –

Following 5 basic problems Tata were facing –

- Inefficient legacy systems.

- Information was distributed over a multiple departments.

- Process of loading and retrieving data was slow and inefficient.

- Production rate was slow because of the ineffective information flow.

- Cost occurred in handling the outdated legacy system was high.

Que 2. What were the basic solutions of the problems?

Ans –

There were following solutions –

- Replacement for slow legacy system

- A centrally stored independent integrated enterprise was needed

- Real time access to data base and better data quality was in need

Que 3. Why Tata went with SAP?

Ans –

Tata choose SAP because of the following reasons –

- SAP was the clear leader in the market for such kind of needs and solutions

- For automotive industry it was the best package

- SAP covers multiple modules and functionalities for different departments.

Que 4. Represent graphically, year-wise implementation process?

Ans –

Que 5. Briefly describe the objective of the study?

Ans –

- Centralise business process across all departments and manufacturing units.

- Increase productivity and improve efficiency by reducing duplication of data entry.

- Reduce the operational cost caused by the outdated legacy system.

- Reach the customer effectively and reply to the quires quickly.

Que 6. What benefits Tata experienced after the SAP implementation and what future plan Tata should follow?

Ans –

Benefits –

- SAP provided them an integrated enterprise.

- Tata financially benefited because of the reduced cost of handling inventories.

- Generating trade documents and analysis of reports became easy.

- Reduction in time taken and better decision making is now possible.

- Now Tata is using a single unified database which is easy to maintain.

Future Plan –

Tata motor is now experiencing a better work process because of the SAP automation. They have the largest implementation of SAP solution in the automobile industry.

Tata should now keep following all the new updates which SAP provides to ensure the up-to-date technology, applications and enhancements. They should keep looking for more areas of their work where automation is needed to achieve better production and functionality. Giving proper SAP training to their existing employee is an important task ahead for them. With the help of SAP, Tata should think about enlarging it’s footprint in the global market as well.

——-x——-

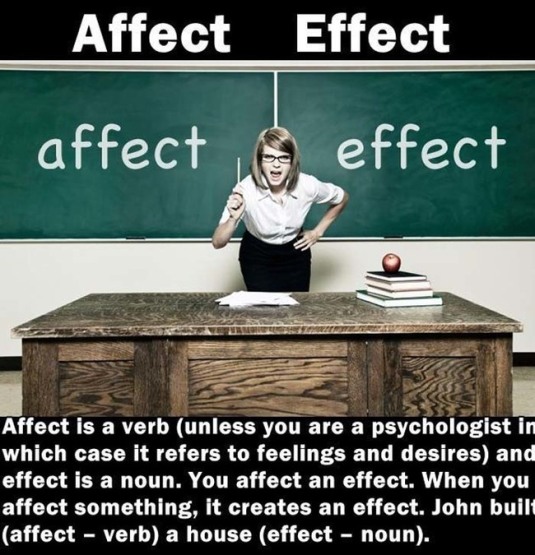

Difference between Affect and Effect

Difference between Affect and Effect Difference between Great Britain and United Kingdom.

Difference between Great Britain and United Kingdom. Difference between Sex and Gender.

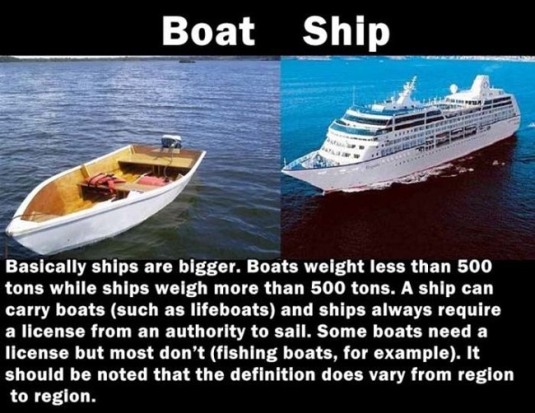

Difference between Sex and Gender. Difference between Boat and Ship

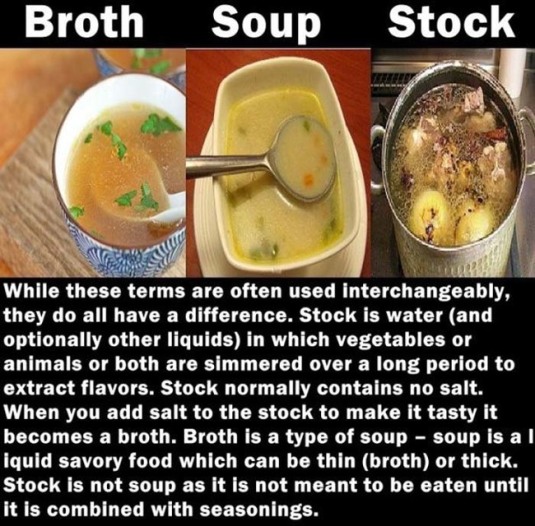

Difference between Boat and Ship Difference between Broth, Soup and Stock

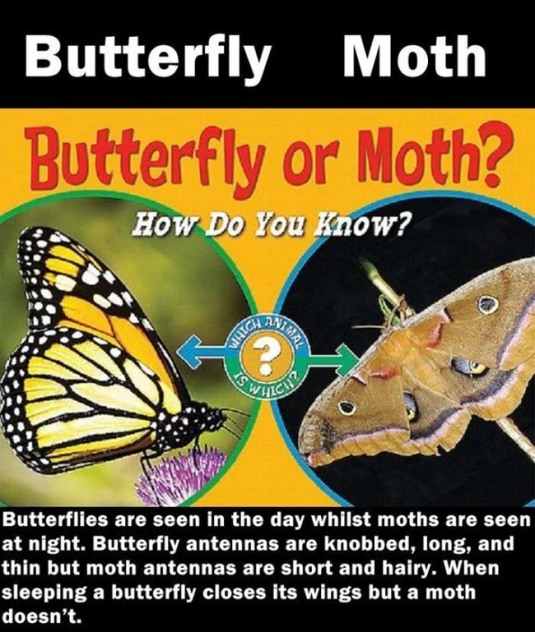

Difference between Broth, Soup and Stock Difference between Butterfly and Moth.

Difference between Butterfly and Moth. Difference between Mass and Weight.

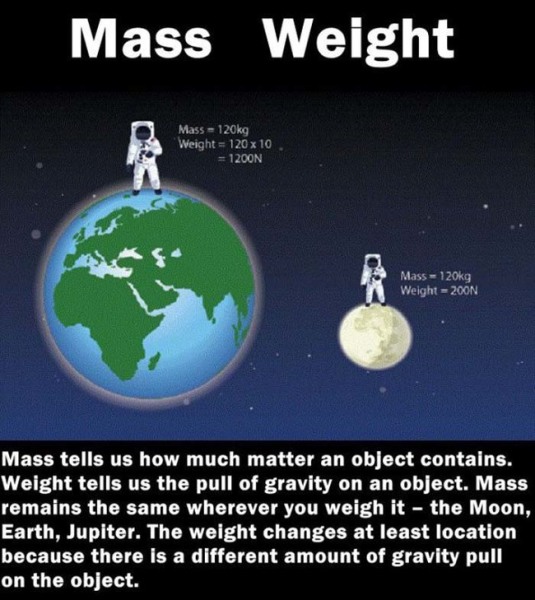

Difference between Mass and Weight. Difference between Lobster and Crayfish.

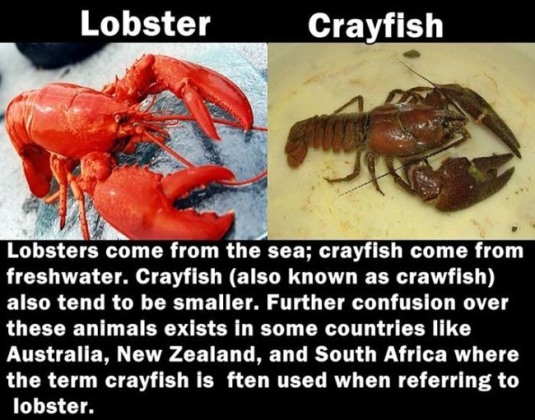

Difference between Lobster and Crayfish. Difference between Coke and Pepsi

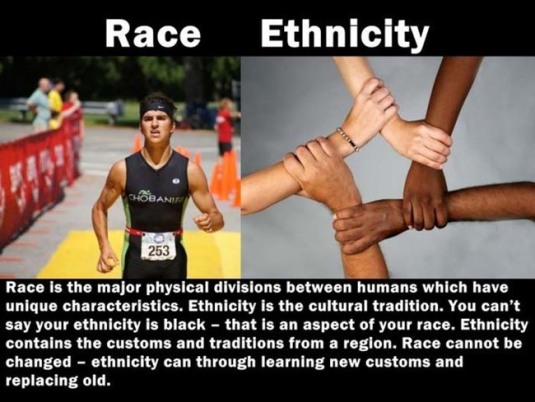

Difference between Coke and Pepsi Difference between Race and Ethnicity

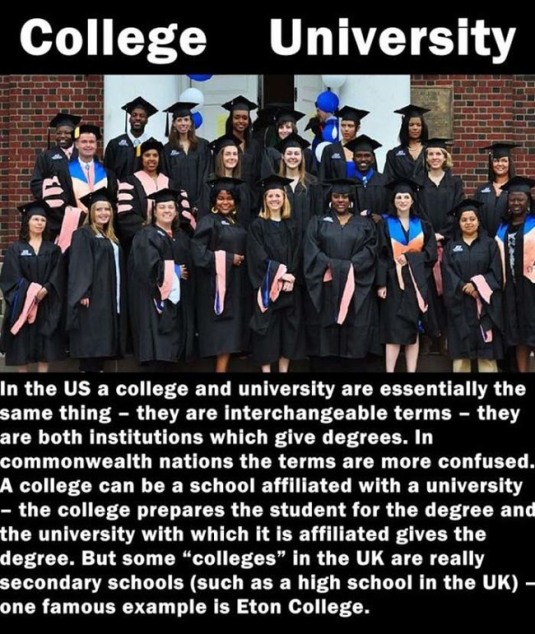

Difference between Race and Ethnicity Difference between College and University

Difference between College and University Difference between Ghost and Ghoul

Difference between Ghost and Ghoul Difference between Cyclone and Hurricane

Difference between Cyclone and Hurricane Difference between Crocodile and Alligator

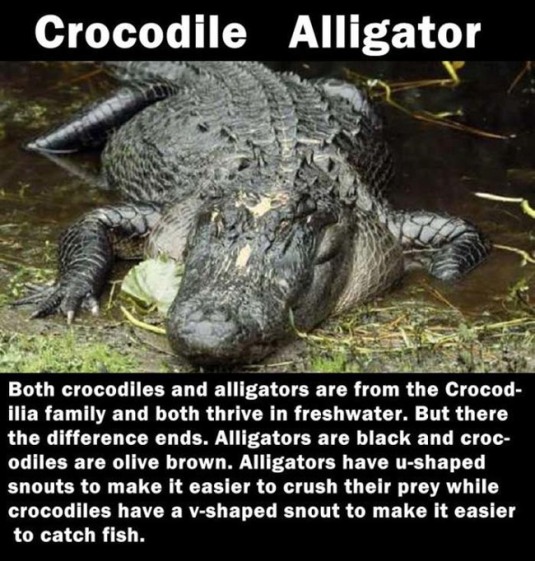

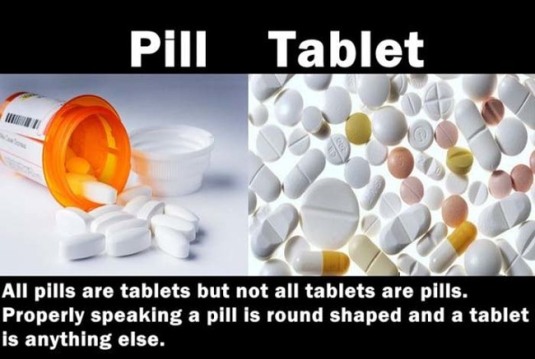

Difference between Crocodile and Alligator Difference between Pill and Tablet

Difference between Pill and Tablet Difference between Weather and Climate

Difference between Weather and Climate Difference between Shrimp and Prawn

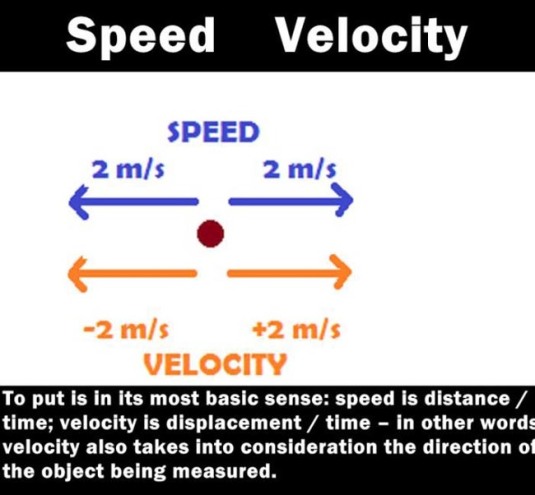

Difference between Shrimp and Prawn Difference between Speed and Velocity

Difference between Speed and Velocity Difference between HIV and Aids

Difference between HIV and Aids